DIRECT CURRENT ELECTRIC MOTORS (DC)

Wajax | Delom is a key partner in the maintenance and the protection of your critical equipment’s productivity. For the past 50 years, our specialists have been repairing, rewinding and maintaining thousands of DC electric motors of all sizes and for all types of industries.

Wajax | Delom has developed predictive and preventive maintenance programs specifically for DC electric motors. When it comes to the maintenance and repairs DC electric motors, trust our expertise.

Since the 19th century, DC electric motors have been a key element in the world’s industrial production. Though today they tend to be replaced by AC electric motors, they remain a vital part of operational needs in mining, pulp and paper production, rail transportation as well as in the excitation systems of midsize hydroelectric power plants.

In order to ensure that DC electric motors operate smoothly, our experts must carry out several specific adjustments during refurbishment operations. In addition, while starting up the unit in your premises, they take into account peripheral settings such as load, power supply data, operational temperature, humidity and contamination so as to ensure top performance.

TYPES OF DC ELECTRIC MOTORS

- Shunt-wound electric motors

- Separate excitation DC electric motors

- Series wound electric motors

- Compound-wound electric motors

- Shunt regulator electric motors

- Double armature electric DC motors

- Direct current traction motors

- Wind pitch motors

- Equipotential lines

- Shunt-wound generators

- Series-wound generators

- Compound-wound generators

- Separate excitation DC generators

- Motor-generator set (MG set)

- Amplydines converter

- Rototrol converter

services

- Installation and on-site start-up

- Diagnosis and repair

- Technical support

- Vibration analysis

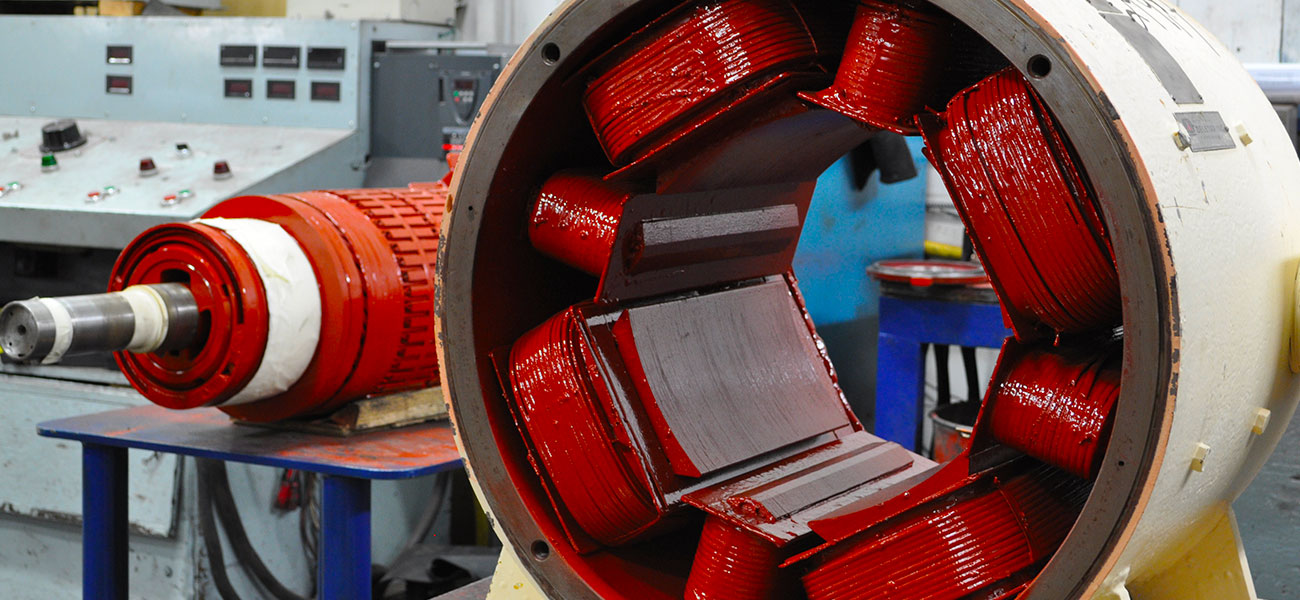

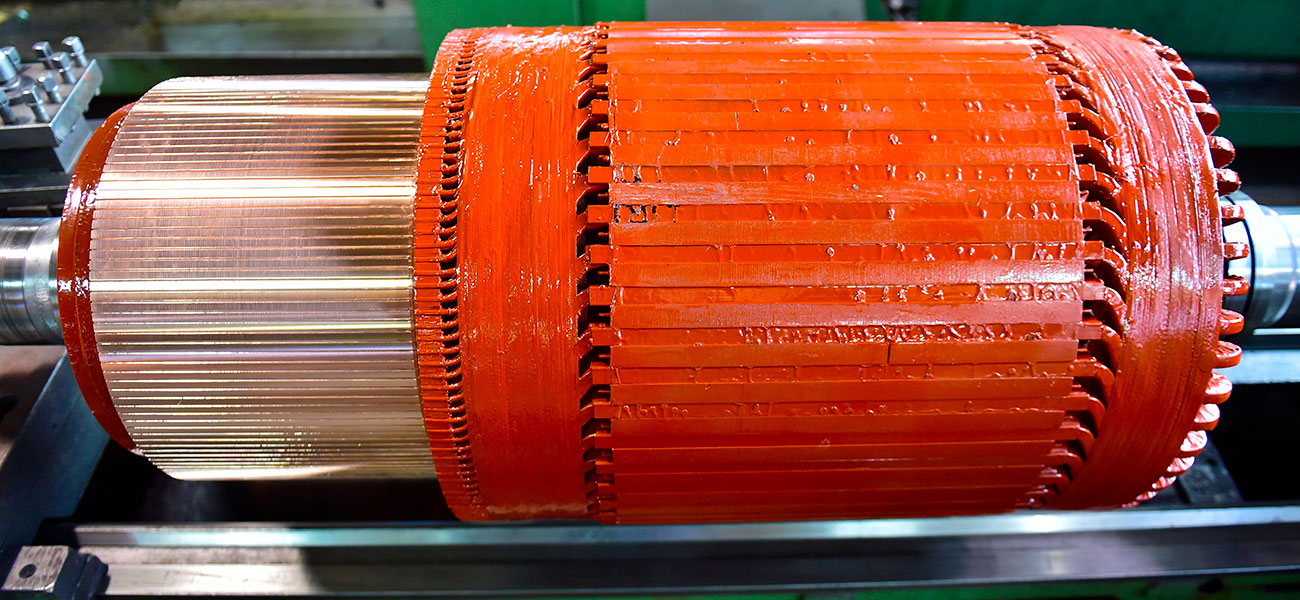

- Armature rewinding

- Armature magnetic circuit re insulation

- Field pole rewinding

- Line bore re insulation

- Shunt field pole rewinding

- Main field pole rewinding

- Commutator machining and undercutting

- Commutator replacement

- Manufacturing equalizer connectors (all types)

- Full commutation system overhaul

- Brush holder refurbishment

- Brush/brush holder/springs replacement

- Coupling repair

- Troubleshooting of commutator spark issues

- Honing according to issues

- Specialized services for commutation issues (patina adjustment)

- Reverse engineering of the commutation system

- Brush selection assistance

- On-site unit cleaning

- On-site commutator machining

- On-site commutator profiling and undercutting

SPECIALIZED WORKSHOP