ALUMINUM SMELTERS

THE DELOM ADVANTAGE

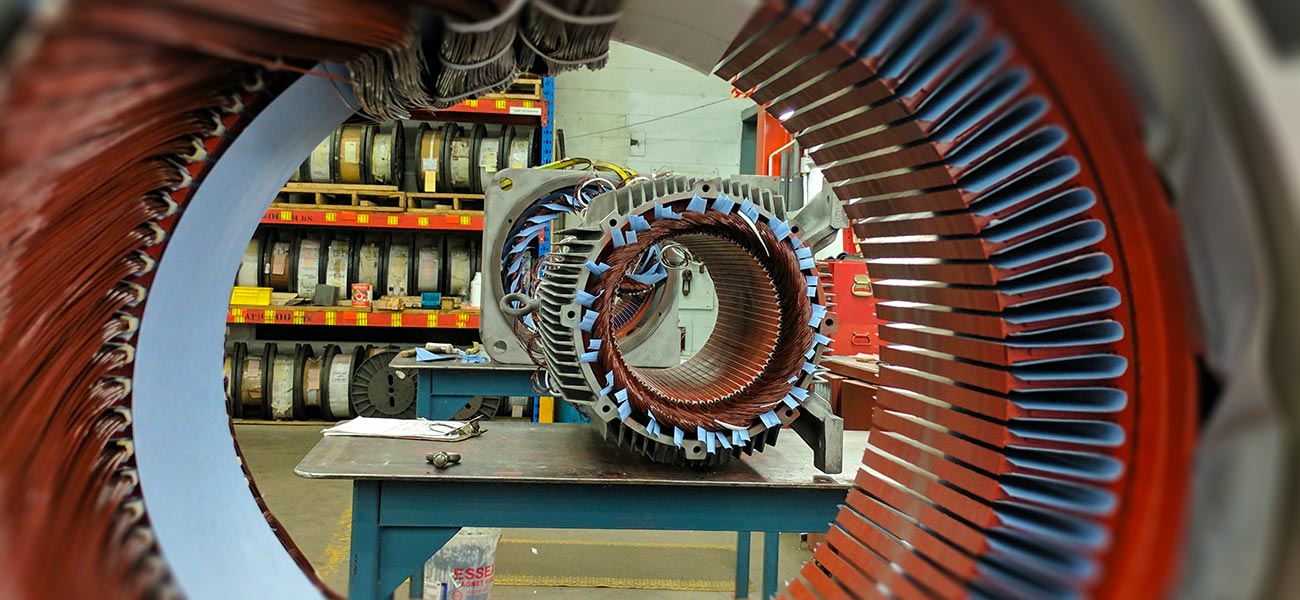

Delom Services has a broad expertise in repairing, refurbishing, and supplying electric motors that meet the needs of aluminum smelters. Working closely with local teams, our experts work to increase unit energy efficiency by improving components through an analysis of the root causes of failure or by choosing replacement units that are more energy efficient. Wajax | Delom provides access to all major manufacturers of new motors available for purchase. We have a large inventory of electric motors and the necessary workforce in place to quickly carry out minor modifications that may be required for applications specific to aluminum smelters. Our workshops are also equipped to receive, decontaminate, and repair electric motors contaminated with beryllium.

Wajax | Delom also provides replacement inventory management support. This program allows, among other things, for the optimization of the quantity of motors stored based on how critical their applications are and how rare the required motor characteristics are. It also allows for a better distribution of the spare motor inventory between multiple sites of the same company, which gives rise to considerable economies of scale. All of this is available online through the Delom+ platform.

Alumina production is an energy-intensive process, and several sites have their own electrical power stations. Wajax | Delom’ extensive expertise allows it to repair or refurbish alternators for hydroelectric power generation for such private power stations.

Trust Wajax | Delom to protect your productivity.

DELOM AND THE INDUSTRY

Aluminum is at the heart of lives. In North America, the industry is mature, and most smelters were built several decades ago. Today, some sites must double their efforts to remain efficient and productive, to lower their prices, and reduce their production costs. Their competition comes from both the external environment and from more recently built smelters within their own business group. Production lines are stretched to their limits, surpassing their initially projected capacity and must do so with minimal unplanned downtimes. In addition, many electric motors selected when the plants were built are no longer available. Equivalent alternatives, when available, vary in size and dimension, which greatly increases the vulnerability of the production line and procurement lead-time.

In this context, reliability and energy efficiency are important factors that determine profitability, and Wajax | Delom is a partner of choice to meet these goals.

- Conveyor electric motors

- Ventilation electric motors

- Hoist electric motors

- Conveyor motor reducers

- Gearmotors

- Radial saw electric motors

- Extruder electric motors

- Uncoiler electric motors

- Circulation pumps

- Submersible pumps

- Coiler electric motors

- Blower electric motors

- Stack fan electric motors

- Dry-type transformers

- Alternators for hydroelectric power generation

- Blower wheel balancing

- Blower repair

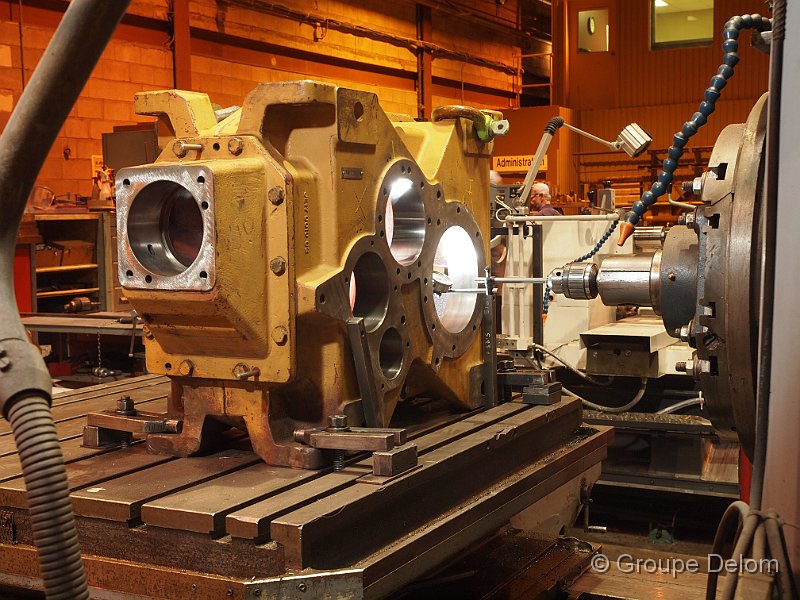

- Gearbox repair

- Industrial pump repair

- Babbitt bearing repair and manufacturing

SPECIALIZED WORKSHOP