SYNCHRONOUS MOTORS AND ALTERNATORS

Delom Services is a one-stop shop specializing in the repair, rewinding, reliability and complete on-site service for synchronous motors and alternators regardless of the power or speed. Delom Services specialists can take care of integral solid poles, salient poles or salient poles with removable horns at our shop or on-site 24/7.

Synchronous electric motors and alternators are mainly high-power machines used for heavy industrial applications and for power generation (hydroelectric, thermal, cogeneration and wind power). Its extensive experience makes Delom Services a key partner in the maintenance, repair, and the manufacturing of spare components for any type of synchronous machine.

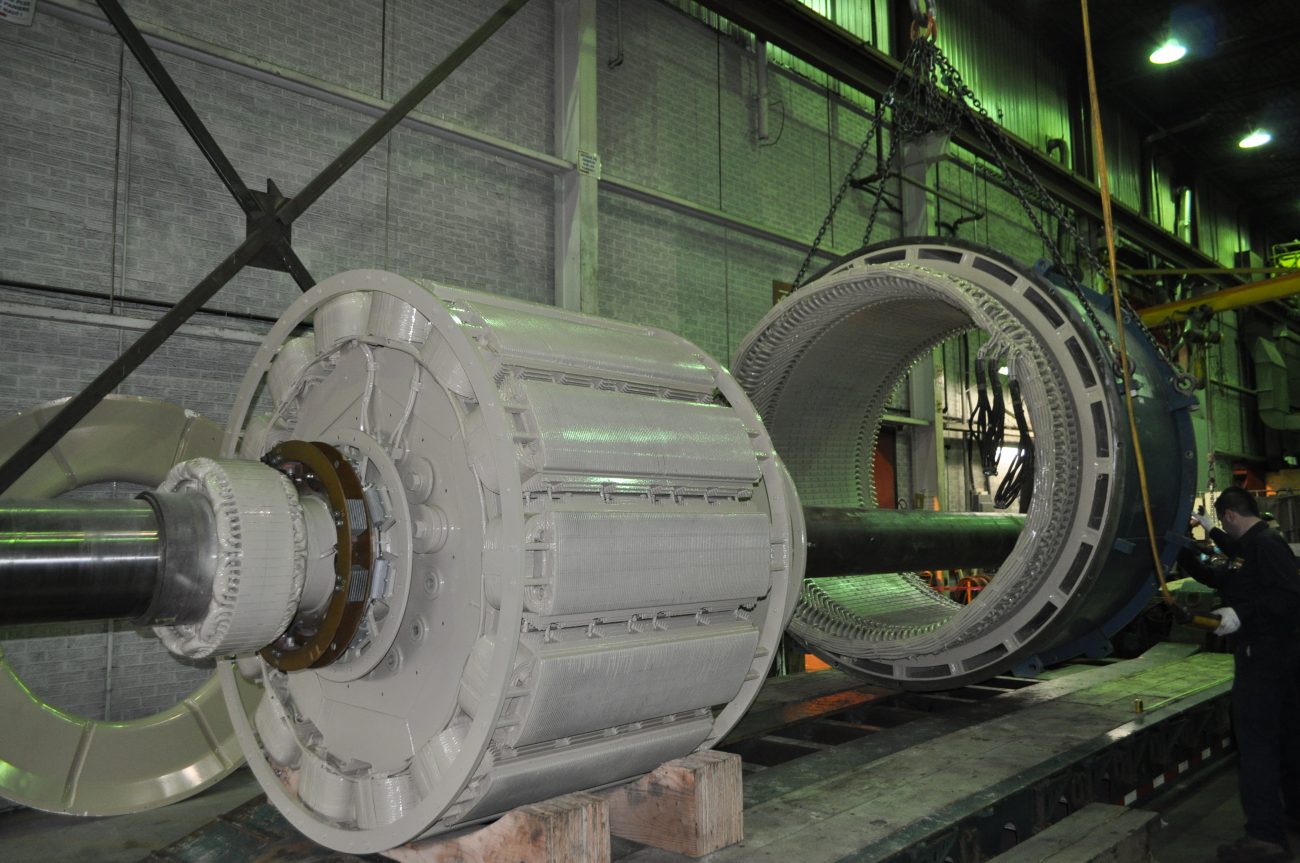

SALIENT POLES ROTORS

HIGH SPEED

The rotors of these synchronous machines have a minimum of four field poles.

Units with lower pole count (4 to 8) are mostly used for compressors, refiners or, in a power generation application as synchronous condensers or alternator.

This type of motor conception, while more economical than integral poles is subjected to very high thermal stress at start-up. These types of stress cause mechanical and dielectric problems. Delom Services developed advanced methods of insulation, connection and mechanical locking which improve both the sturdiness and lifespan of such units.

Electrical and mechanical overhauls are entirely conducted by our specialists for every single component: Babbitt bearings, exciter, heat exchangers, connectors and winding up to 13 kV.

In addition, we offer a complete set of reliability services.

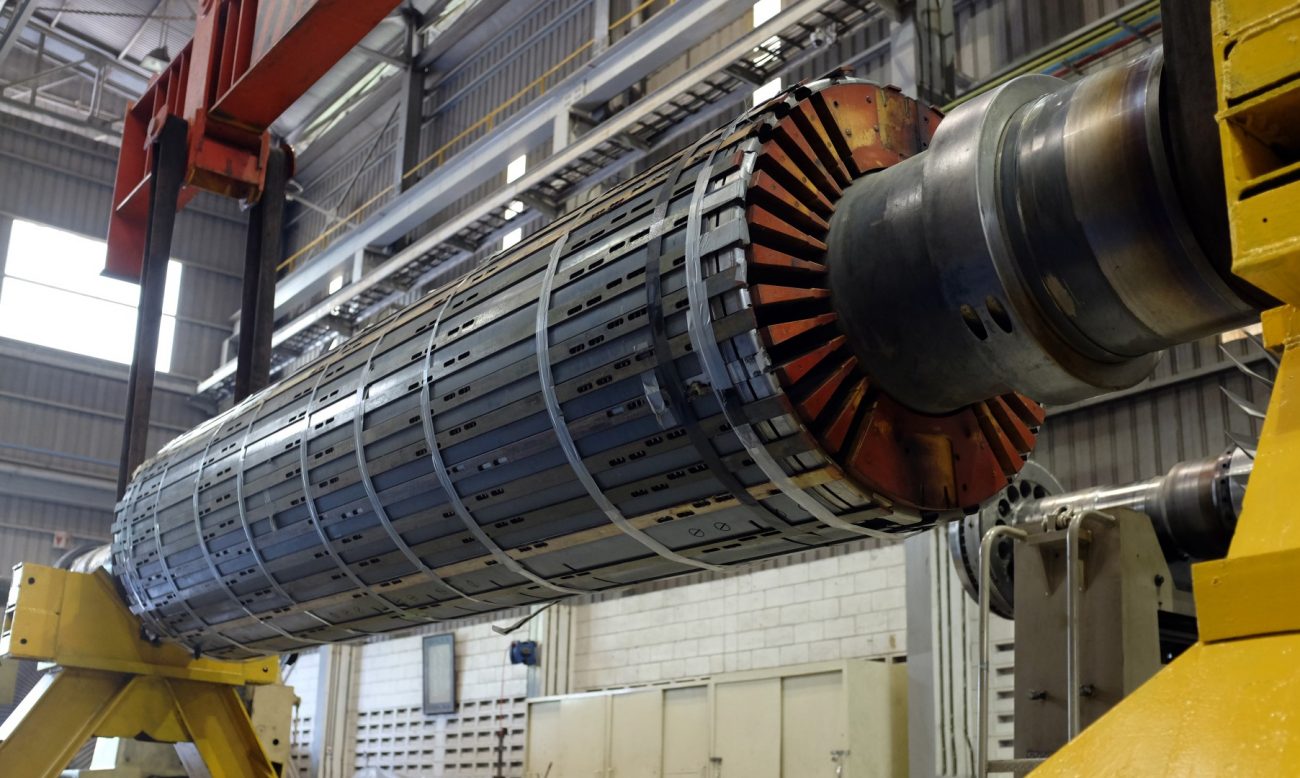

LOW SPEED

For high pole numbers applications (more than 10), salient pole rotors are found in grinders, crushers, pelletizers, wind or hydropower generation, etc. Delom Services can provides VPI impregnation for synchronous electric motors (stators and rotors) of up to 16 feet in diameter. We also manufacture all types of poles (round wire, rectangular wire and accordion poles).

We offer a full range of on-site services, including rewinding, for units over 16 feet in diameter or when the site’s layout prevents complete stator removal.

Electrical and mechanical overhauls are entirely conducted by our specialists on every single component: Babbitt bearings, exciter, heat exchangers, connectors and winding up to 13 kV.

In addition, we offer a complete set of reliability services.

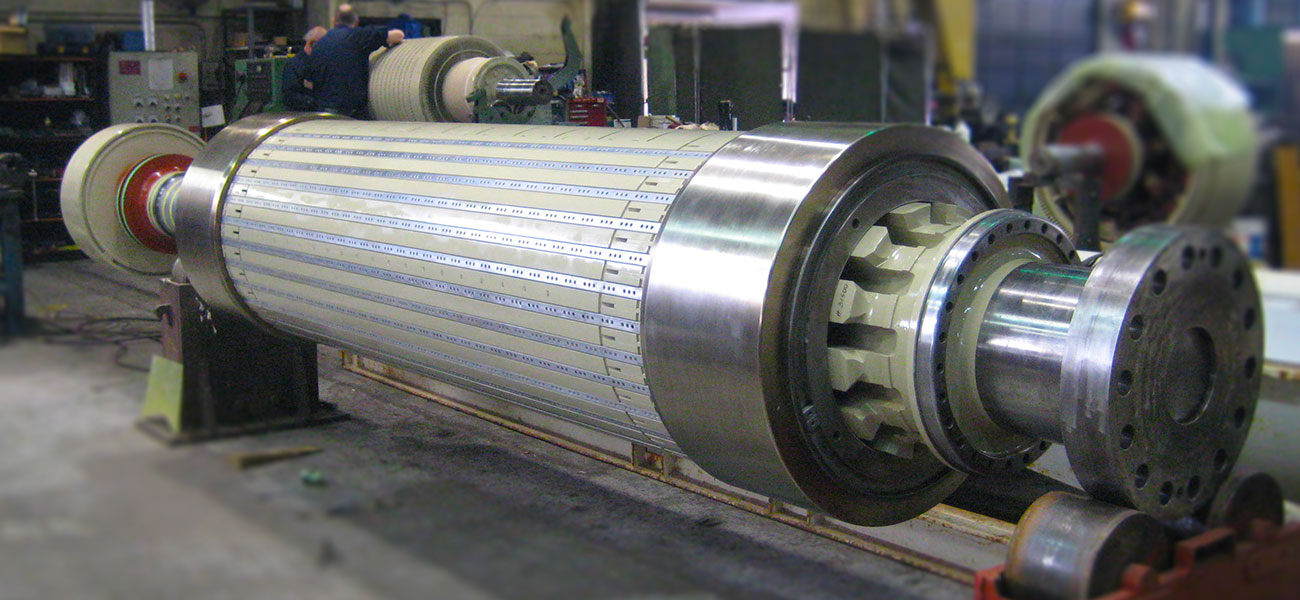

INTEGRAL POLES ROTORS

Integral pole rotors are less common and are usually found where:

- Startups are frequent

- Startup torque is more demanding

- The power grid is more fragile

Because they are designed to minimize heating up at start-up and for high-performing thermal exchange, the rotor is mechanically more robust compared to a salient motor. However, this type of synchronous machines is more expensive to purchase.

Given their design, it takes sharp expertise to manufacture or overhaul these units and our teams have acquired extensive experience with such units over the past decades.

For rectangular wire poles, Delom Services has invested in customized equipment made especially to wind these tall integral poles. We use high performance epoxys providing great thermal conductivity and optimal mechanical performance.

For accordion poles, the complete insulation overhaul of ground insulation and insulation between turns is conducted directly on the rotor pole.

Delom Services has developed enhanced insulation, connection and mechanical locking methods that improve the machine’s sturdiness and overall lifespan.

We guarantee a performance equivalent of better compared to the original design.

Electrical and mechanical overhauls are entirely conducted by our specialists on every single component: Babbitt bearings, exciter, heat exchangers, connectors and winding up to 13 kV.

In addition, we offer a complete set of reliability services.

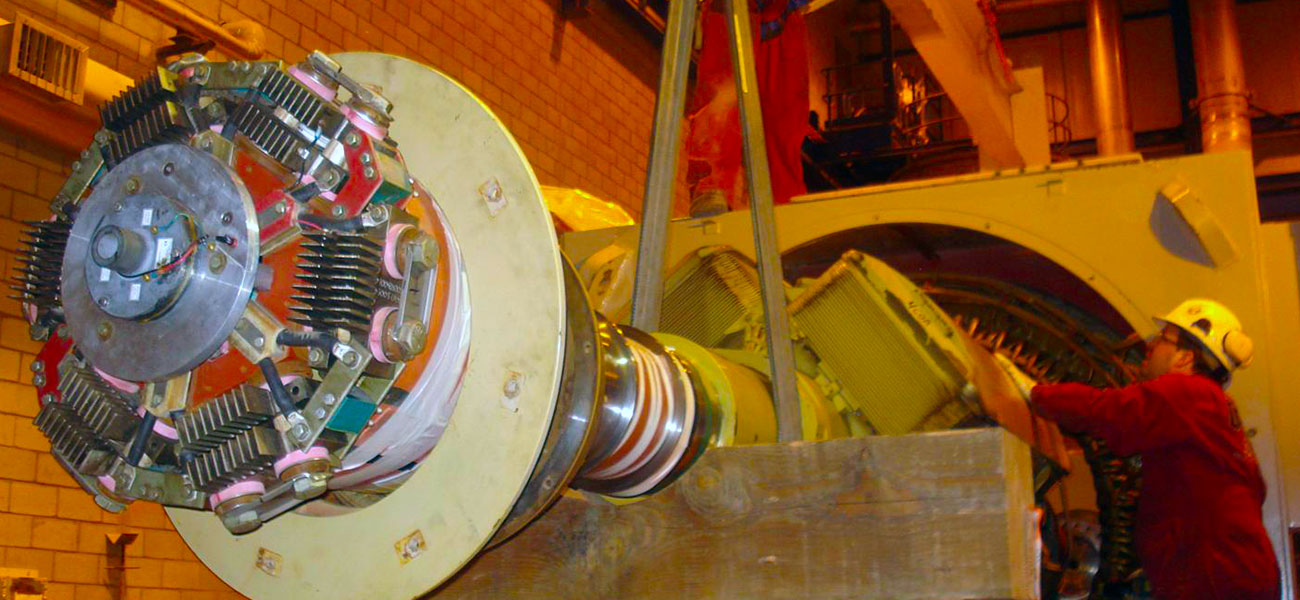

TURBO GENERATORS

Turbo generators are used in high-speed applications to produce electricity using steam (cogeneration, coal, thermal power plants nuclear power and shale gas).

These small diameter rotors are subjected to enormous centrifugal and magnetic forces that are proportional to the unit’s power. The coils, which constitute the two poles, are fully integrated and wedged in slots at the periphery of the rotor.

Design and manufacturing of these coils require extreme precision and so does the winding process.

Once the coils are inserted, retaining rings are installed on the coil heads and their connections. Precise adjustment of the rings will ensure optimal performance of the mechanical, electrical and environmental aspects of the turbogenerator.

Experienced winders, mechanics and engineers from Delom Services’ team provide turnkey solutions for the installation, operation and maintenance of these complex units and have been doing so for more 50 years.

SPECIALIZED SERVICES FOR SYNCHRONOUS ELECTRIC MOTORS AND ALTERNATORS

- EXCITER

- Exciter rewinding

- Exciter reverse engineering

- ROTOR

- Salient poles dismantling (on-site or in our shop)

- Turbogenerator coil manufacturing

- Core reinsulation

- New pole manufacturing

- Rotor winding

- Retaining ring replacement

- Safe asbestos abatement

- Shaft repair

- Shaft replacement

- Shaft machining

- Bearing seat machining

- Bearing seat insulation via thermal spray coating

- Collector ring repair, replacement and machining

- On-site pole replacement

- STATOR

- GENERAL

- Repair of damage housing

- Soft foot repair

- Bore repair

- Spare parts manufacturing

- VPI, hybrid or B-stage insulation systems

- Safe asbestos abatement

- Bonding under constant heat and pressure

- Insulation systems reverse engineering

- Reverse enginnering of the insulation to allow use of variable frequency drive (VFD)

- Ratio change

- Power

- Voltage

- Speed

- Frequency (60 Hz-50 Hz)

- Probe installation or replacement (temperature, proximetric, speed, vibration, etc.)

- Bearing replacement

- Babbitt bearing replacement

- Babbitt bearing manufacturing

- Cooling pipes maintenance and repair

- Heat exchangers maintenance and repair

- Root cause of failure analysis

- Final tests

- Electrical tests

- Tests in rotation

- Load test

- On-site maintenance and repair

- Complete machining services

- Emergency service 24/7

RELIABILITY SERVICES FOR SYNCHRONOUS ELECTRIC MOTORS AND ALTERNATORS

- Infrared camera

- Complete mechanical inspection

- Laser alignment

- Complete electrical tests

- On-site operational settings adjustment

SPECIALIZED WORKSHOP