HYDRO POWER GENERATION

THE DELOM ADVANTAGE

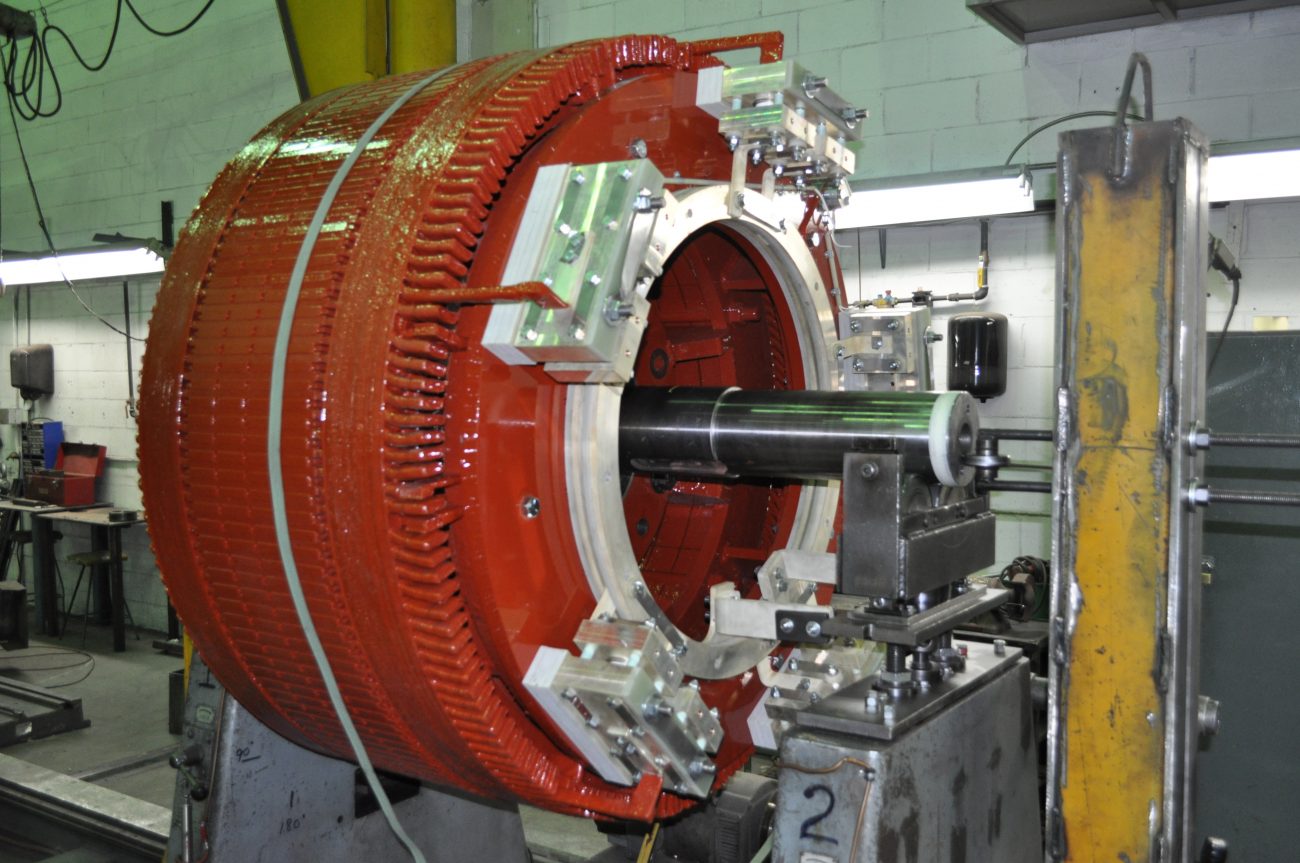

Delom Services is a key partner in the renovation or refurbishment of generator sets in a hydroelectric plant. With decades of experience, we offer a complete service for reverse engineering, winding and refurbishing units. We manufacture our own VPI or B-Stage coils, have a 16 ft. (4,80m)-diameter VPI tank and we have teams of engineers, winders and technicians who mobilize for work on site.

Covering all aspects of hydroelectric plant refurbishment allows Delom Services to substantially reduce repair times in the event of a break and to maintain quality control throughout the process. In addition, we support the entire unit (rotor, stator and exciter), and we ensure a precise fit of all refurbished components, thus reducing installation time.

DELOM AND THE INDUSTRY

When refurbishing or rewinding a generator set in a hydroelectric plant, mechanical and electrical constraints prevent major changes to the original designs. However, new materials and new technologies allow upgrades that do not require alterations to older civil structures. These upgrades have many advantages: they improve the performance and uptime of the unit, but above all, since they do not require major changes to civil engineering, they can be performed within a shorter timeframe, which allows the unit to be restarted promptly.

CONVERTING A DIRECT CURRENT EXCITER TO A ROTATING DIODE

The conversion of a DC exciter to a rotating diode offers many advantages other than the obvious saving of maintenance time due to the removal of the commutating system, which results in increased availability of the machine.

In fact, this patented process, developed in partnership with Hydro-Québec and the University of Artois, will use the same structure again and will have pretty much the same weight, eliminating the need for structural evaluation, which can be long and expensive. The exciter stator and rotor windings are completely redesigned to work with a diode bridge instead of carbon brushes and a commutator. The main shunt breaker is also removed.

Each exciter presenting its own difficulties, the entire design is provided by the experienced team of Delom Services and entirely made in house.

A conversion to a rotating diode exciter should always be considered when refurbishing a small or medium-sized hydropower plant, as it offers many advantages:

- Increased machine availability

- Elimination of conductive carbon dust contamination in the exciter and alternator

- Maintenance shutdowns are significantly reduced

- Use of the original structure

- Same weight constraint on the main shaft

- Same response time on the transport network

- Elimination of main circuit-breaker

WORK – Stator

- Removal of interpoles

- Manufacturing of new VPI poles

- Machining of the housing

WORK – Rotor

- Removal of the commutator

- Removal of the collector rings

- Manufacturing of new coils and complete rewinding

- VPI insulation

- Installation of the rectifying bridge

WORK – Project

- Removal of shunt breaker

- Measurements at the plant

- Electrical and mechanical design

- Electrical and mechanical simulation

specialized workshops